Sustainability

Company

Sustainable machinery, a commitment to the environment.

Industry 4.0 Machinery

Designing sustainable machinery that is as respectful as possible to the planet is one of the main objectives of the TecAIRE brand when creating machinery. And it is that on many occasions it seems that terms such as industry, machinery or factories are against sustainability.

It is clear that the resources of our planet are limited and therefore we have a firm commitment to the environment.

In this aspect, it is key to keep in mind that thinking only about the productivity of a machine or a factory, entails irreversible environmental consequences. That is why it is part of the ECO-EFFICIENCY. That is, that the reduction of the environmental impact in relation to the volume of production is reduced. In other words: We want TecAIRE machines to be as productive or more productive than in the past, but for environmental consumption to be reduced.

With the aim of reducing all direct emissions, different initiatives have been considered such as:

- The digitalization of internal and external processes (operational with customers and suppliers)

- The acquisition of electrical machines, which already account for 90% of the total machinery available in the manufacturing area.

- Remote maintenance of machines thanks to the IoT to avoid unnecessary displacements.

1. Wiring of machinery and facilities.

The main supplier of electrical wiring consumes electricity in its factories and facilities in Spain 100% of renewable origin.

The coils, which carry the PEFC™ Certificate for Sustainable Forest Management, which have been consumed for more than a decade, offer the guarantee that the wood used as a raw material comes from forests managed in an environmentally friendly manner.

2. Motors.

It is about adapting the drive technology to reduce energy consumption. In a sector as large as manufacturing, what is apparently a minimal change – since it refers only to certain parts, and not to complete machines – has a huge impact. In fact, the EU estimates that Regulation (EC) 640/2009 alone will save 102 TWh of energy by 2030, and that Regulation (EU) 2019/1781 will result in additional savings estimated at 10 TWh per year.

The key is to have a comprehensive vision in which all components are efficient to perform a real and detailed analysis of energy consumption and act accordingly.

TecAIRE has electric drive suppliers that reaffirm their commitment to SUSTAINABILITY and their commitment to energy efficiency, seeking to reduce their carbon footprint to the atmosphere by incorporating an intelligent and centralized system of facilities management, , the placement of photovoltaic panels, the notable improvement of the thermal envelope of the building, installation of LED systems with regulated DALI, efficient air conditioning system, incorporation of parking spaces with electric charger, etc.

3. Automation.

Siemens, the main supplier of the material for automation and drives in the machinery, reduces CO2 emissions in Spain by 90% and globally by 54%.

Siemens has reached the intermediate target they had set for the reduction of carbon emissions. The company has reduced the carbon footprint of its production chain by more than half (54%) since 2014. With this mark, Siemens has exceeded, by four percentiles, its goal of halving its global carbon dioxide (CO2) emissions by 2020. Including Siemens Energy, this percentage represents around 1.2 million tonnes of CO2 compared to its 2014 levels.

In the case of Siemens Spain, this figure is even higher. Thanks to the use of renewable sources to provide energy to its facilities, as well as improvements in efficiency and use of a fleet of hybrid and electric cars, it has been possible to achieve a 90% reduction in CO2 emissions compared to 2014 data.

Sustainability initiatives are an essential aspect of successfully implementing Siemens’ Vision 2020+ Strategic Program. The understanding of sustainability is fully based on the values of the company: responsible, excellent, innovative. At Siemens, sustainable development is defined as the means to achieve profitable and long-term growth. In doing so, externally, it aligns with the goals of the UN 2030 Agenda for Sustainable Development, while, internally, it strives to balance people, the environment, and benefits.

4. Commissioning and maintenance.

The remote maintenance of TecAIRE machines and installations thanks to the IoT avoiding unnecessary displacements.

Thanks to the internet, the number of physical trips worldwide to carry out the commissioning and maintenance of machines and facilities has been reduced.

QH.

The flue gas burners used in TecAIRE installations are standardised and normalised with the aim of achieving greater sustainability.

CREMAX is particularly active in the alternative energy sector. We can supply burners for alternative fuels. In addition, the range has been extended with fuel burners for renewable energy sources that promote sustainability.

The design and study of the new low emission heads (LOW NOx), the electronic air-fuel control regulations together with the incorporation of variable frequency drives in the engines and the control of O2 oxygen in combustion, increases energy savings considerably and better respect for the environment.

5. Manufacturing.

The manufacture of TecAIRE equipment is carried out with sustainable materials as much as possible:

Steps are taken in the manufacturing plan to avoid waste such as outsourcing of machining processes in which they are carried out through long runs and not manufacturing piece by piece.

It is manufactured using iron, stainless steel or aluminum sheets that already comes with the shape defined by laser cutting to avoid the disposal of materials generating unsustainable waste.

The gases used for welding are certified by AENOR with the ISO 14001 standard; its production process is part of the clean and non-polluting industry since the obtaining of nitrogen, oxygen and argon is based solely on physical processes, using air as a raw material. However, the separation of compounds from the air is an energy-intensive process.

All welding machines have been renovated in the last year generating less energy consumption, The manufacturer of welding machines “SOLTER” is committed to the environment; develop their products with energy-efficient INVERTER technology that incorporate solutions such as the “Stand-By” disconnection system focused on energy saving.

6. Office, administration and technical department

he electricity contracted in the company is 100% renewable energy.

An internal culture of the non-use of plastics for the consumption of packaging during the working day is being motivated, thus contributing to generate less waste.

The 3D and PLM design system has been implemented that helps to not generate unnecessary printed documentation during the day-to-day work.

Work with TecAIRE

Company

Work with us

Are you looking for an innovative company in the industrial sector where you can grow and develop professionally? Work at TecAIRE. At our company, we value our employees and allow them opportunities for growth and development. We are experts in the design and manufacture of industrial machines for coffee and cocoa production. We offer innovative and efficient solutions for coffee and cocoa roasters, coffee grinders and complete industrial plants for both products.

If you are looking to join a company committed to employee welfare, sustainability and development in the industrial coffee and cocoa sector, don’t hesitate to apply to work with us! In our company you will have the opportunity to develop professionally and contribute to a more sustainable future.

innovative, creative and proactive engineers

- Because innovation policy, together with collaboration with customers, leads to the best results.

- Because the quality and experience of the engineering team provides the best guarantees of product safety and conformity, adapting to the legislation and climatic conditions of each country.

- Because the integration of all services, including manufacturing, allows us to be the fastest and most competitive.

- Because industrial machines and installations are the most reliable, robust and durable on the market.

- Because the maintenance, after-sales and customer service has worldwide coverage and assistance, covering any country in the world, either with its own staff or with approved local technicians...

- Because the TecAIRE guarantee allows the equipment to be operational in any condition, and under any incident, and anywhere: the technical equipment, both its own and approved local, will help to solve any anomaly, whatever the problem to solve.

- Because every customer is looked after with care and service is provided 365 days a year.

- Because the network of trusted partners makes it possible to rely on local or specialist services when needed.

- Because TecAIRE is a world leader in the manufacture of equipment for roasted coffee and hydraulic cylinder grinders.

10

Reasons to workwith TecAIRE

- Innovative, creative and proactive engineers.

- Responsive and flexible project management.

- Our technological innovation policy.

- Product safety and conformity, worldwide.

- Speed and competitiveness.

- Our machinery and facilities are the most reliable, robust and durable on the market.

- Maintenance and after-sales service provided by our own or approved staff, available anywhere in the world.

- Guaranteed functionality of our equipment, thanks to engineering and service teams made up of our own or approved staff.

- Our services are available 24/7, 365 days a year.

- Global network of trusted partners.

Company

Si te gusta trabajar en equipo, en un entorno dinámico y joven y tienes vocación de servicio al cliente, TecAIRE es lo que estás buscando. Rellena éste formulario con tus datos y adjunta tu curriculum vitae y nos pondremos en contacto contigo. Muchas gracias!

Corporate Social Responsibility

Company

Commited to the environment

TecAIRE is committed to Corporate Social Responsibility, implementing sustainable practices and promoting a positive impact on the community and all our operations. We work to improve employee conditions, minimise environmental impact and support local organisations. We actively contribute to build a better and sustainable future.

As a company in the industrial sector, we are committed to Corporate Social Responsibility by implementing sustainable practices in all our operations. We also work to improve working conditions, develop efficient and sustainable solutions for the industrial sector. Some of our main actions are:

- Company committed to the environment.

- Strict compliance with the legal regulations of each country.

- TecAIRE equipment respects the strictest food safety standards.

- TecAIRE adapts to the most demanding environmental regulations.

- Design and manufacture of industrial machinery that aims to reduce energy consumption.

- Development of industrial processes with low energy consumption.

- Integration of the use of clean and renewable energies.

- Integration of water recycling systems.

- Care in the quality of life of the workers of our clients with automatic processes and ergonomic machines, safe and easy to use by the workers.

- We enable the development of local economies by working with regional teams for maintenance work.

- Training of the staff of our clients sharing the knowledge for the economic development of more than 30 countries.

- Continuous improvement of contact and follow-up services so that our clients have the best of partners for the development of their businesses.

- Continuous training of staff to be up to date with the latest trends and technological innovations and allow them an adequate professional development.

Legal regulationsFood safetyEnvironmental regulationsEnergy savingClean energyWater savingQuality of life of the workerEconomic development

Customers

Company

TecAIRE customers

With experience and know-how, TecAIRE has been acquiring more and more customers and consolidating its position in different markets over time. Our customer relationships have always been one of our top priorities. Over the years, at TecAIRE, we have continuously worked to ensure that our customers are completely satisfied with our products and services.

With our long history in the field of industrial coffee and cocoa products, we have a large portfolio of customers who keep on relying on us year after year. This is because we understand the specific requirements of our customers. We help them to achieve their coffee and cocoa production targets in different processing formats. In addition, we work hard to build solid and lasting relationships with them.

We always seek to enhance and consolidate the relationship with our customers. For this reason, we have a customer service and technical service to assist and help our customers at all time in any aspect in which we can provide assistance.

Each of our client relationships represents a challenge to enrich and increase corporate knowledge.

Our relationship with our customers has been fundamental to the success of our company over the years. Nowadays we keep working hard to make sure that customers are always satisfied with our products and services.

TecAIRE is the official supplier for:

Multinational, regional and family firms

Clients special cases

Discover some of the TecAIRE success stories and find the inspiration you need for your new project with us.

For 44 years, whether they are large or small agri-food companies located anywhere in the world, who need to integrate a roasting or grinding process for the production of their final product, have been able to rely on TecAIRE industrial installations.

Special cases

The project consisted of modernising roasting and grinding processes in an end-product processing plant in one of the most prestigious green coffee mills in the whole of Latin America. Knowledge of the raw material, green coffee, was unsurpassed, and the end goal of the quality of the final product, roasted coffee, was perfectly defined and maximum quality demanded. The challenge was to find suitable technology and methods to achieve this simply and efficiently. Two parallel projects were created: one for coffees for export, and the other for coffee to be consumed locally. Bespoke versions of the TNA and TTA roaster range and TEC-ROLL grinders were used. The toasting and grinding plant was modernised and processes automated, resulting in maximum final product quality, bringing production methods in line with the rest of the Group. The toasting and grinding plant is currently on of the most modern in Latin America and is the benchmark for future Group projects.”SEGAFREDO ZANETTI GROUP (Costa Rica – Central America – Coffee)

The project consisted of a completely new roaster, which enlarged an existing processing line, so the new line was much more versatile than the existing line, handling products that were much more difficult to process. The challenge was to manufacture a new product without reference to other producers with other equipment, as the process was completely novel, based on cocoa nibs and powder. The new roaster had to be larger than any manufactured before, producing up to 6,000 kg/h, 24 hours a day. The combination of our engineering department’s expertise and the client’s product knowledge enabled all of the objectives to be achieved. Continuing excellent results are guarantees with the JCP cocoa roasting range, which was created out of this project and is now used in projects in other countries.NETHERLAND (Spain – Europe – Cocoa)

The project was to build a roaster that could process nuts, seeds and cereals, using extremely versatile and modern systems to precisely replicate very traditional products. The Middle East is an extremely demanding region for dried nut, seed and cereal production, as their dietary and religious traditions are based on these. Automation and flexibility in the design of the new CRG roaster meant that it could adapt to air flows, operating temperatures and synchronisation speeds to precisely replicate traditional processes using the most modern technology possible, ensuring food safety and process reliability. Today, this technology is applied on a larger scale in many countries in the region. The new technology has enabled these products to be exported between countries in the Gulf area, while complying with strict international food regulations in full.AL DAHRA (United Arab Emirates – Middle East – Cereals)

The project was very ambitious and demanding, as it consisted of modernising roasting equipment already in use to comply with the strict environmental standards that the Group wanted to implement in all their factories worldwide. This meant that processes in each of these factories and their relation to the end product had to be understood, although these often varied between factories. Operations in each facility also had to be investigated, and all this information brought together to create a standard, homogeneous solution that could be used in any roaster in the Group, for any end product. The most susceptible equipment was modernised in a very short timescale, causing significant energy savings and reducing atmospheric emissions dramatically, with the investment in time and money optimised to the maximum. Thanks to the ABC-Tex project, other similar international groups adopted the same environmental model, which is now the international standard.NESTLÉ GROUP (America – Europe – Asia – Africa – Quality and Processes)

Who we are

Company

Company specialised in the manufacture of industrial machinery for coffee, cocoa and drying and grinding processes

For more than 44 years, TecAIRE – Neocafe Engineering has specialised in the design and manufacture of industrial machinery for coffee, cocoa and spices. The world’s leading brands entrust us with their facilities to produce the best flavours of natural or pure and sugar coated coffee, cocoa, roasted cereals (sesame, wheat, corn, tiger nut, chicory, barley, date seed, …), and spices (paprika, onion, garlic, …).

We are a European group, which makes us comply with the most demanding standards of the food industry in terms of safety conditions, design and construction of industrial machinery, and we know how to adapt to the legislation and climatic conditions in every corner of the globe.

We are involved in the entire production process: from the green bean through to the packaging stage, providing a 360° engineering services including consulting, design, production, installation, maintenance and after-sales.

Currently, over 400 projects in 30 countries use our machinery, which is known to be the most reliable, robust and durable on the market.

At TecAIRE – Neocafé Engineering we are more than just engineering. Since 1978, we have made coffee, cocoa and cereal-related ideas and businesses possible for hundreds of clients globally. We are committed to your ideas, and our creativity, experience and expertise are available for you to achieve the quality you require. Tus ideas son nuestro compromiso, ponemos nuestra creatividad experiencia y conocimiento a tu disposición para conseguir esa calidad que necesitas.

Vision, mission, values

The success of our customers is our success

We believe that the secret of the best flavours is the result of our technical expertise and the confidence that our clients place in us.

Our mission is to complete projects to the highest standard for large and small companies, and to turn their ideas into reality.

So we work closely with our clients and foster a culture of constant creativity and technological innovation.

We believe that our clients’ success is our success, and that the human touch and social responsibility are as important as technology.

Excellence

Technology

Innovation

Creativity

Accessibility

Service

Partnership

Our team

The TecAIRE team is made up of 40 professionals.

The TecAIRE team comprises 40 professionals and an extensive network of local partners and specialists integrated into our global coffee, cocoa and cereal project management.

We have different specialised engineering departments are at our client’s disposal: engineering, programming, R&D, customer service and quality assurance.

La oficina técnica cuenta con ingenieros especializados en ingeniería mecánica, eléctrica y electrónica para el servicio de nuestros clientes. TecAIRE has a purchasing and logistics department that carries out the purchase and management of these for the manufacture of machinery

The production process that takes place in TecAIRE’s facilities for the manufacture of machinery being 100% territorial.

The quality and experience of our team is the best guarantee of product safety and conformity. Our staff understands how to adapt to the legislation, culture and climate conditions in each country.

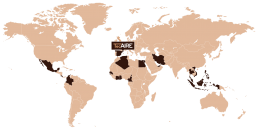

TecAIRE worldwide

Company

TecAIRE in the 5 continents

Commercial agents

- Ho Chi Minh (Vietnam)

- Manila (Philippines)

- Singapore (Singapore)

- Kuala Lumpur (Malaisia)

- Jakarta (Indonesia)

- Bangkok (Thailand)

- Tehran (Iran)

- Dubai (UAE)

- Cairo (Egypt)

- Algiers (Algeria)

- Abidjan (Ivory Coast)

- Dakar (Senegal)

- Accra (Ghana)

- Douala (Cameroon)

- Mexico City (Mexico)

- San José (Costa Rica)

- Bogotá (Colombia)

Based in Terrassa (Barcelona) Spain, TecAIRE is an international European group with a worldwide presence thanks to the internationalisation that it has acquired over the years. At the same time, this global power has been built up thanks to the network of commercial agents we have in 17 countries around the 5 continents.

The 100% of the production of our products are manufactured in Spain, for this purpose we have a 4.000 m2 engineering and manufacturing plant, located 30 km from the international airport of Barcelona and 40 km from the port.

Over 93% of our production is destined for international markets: we have more than 400 installations in 30 countries on 5 continents.

TecAIRE is a leading supplier in some regions such as Southern Europe, Latin America, the Maghreb region and Southeast Asian, where we have a wide network of commercial agents that contribute to expand and branch our international market.

The set-up of the installations and the training of the employees are carried out by our own specialised technicians in order to provide our customers with all the information and optimisation of the complete installations fot coffee, cocoa or drying and grinding processes. In addition, TecAIRE equipment is maintained by our own technicians, possibly accompanied by local technicians.

Company history

Company

44+ years of excellenceTecAIRE since 1978

In 1978 the history of what, over the years, would become the TecAIRE at Terrassa (Barcelona) Spain, with the manufacturing of industrial machinery by Jordi Cabré, a great designer with a passion for the industrial processes of coffee and cocoa. This marks the beginning of the TecAIRE history for coffee and cocoa industrial machinery manufacturing, such as roasters for natural and sugar coated coffee, roasters for cocoa beans and nibs and complete industrial coffee and cocoa installations for customers all over the world.

An absolutely pioneering technology modernises industrial coffee roasting processes, especially for sugar coated coffee, in just a few years. The process is transformed from an artisanal and rudimentary method to today’s fully technified and modernised process with the highest quality standards. It is the first in Spain to be 100% designed and manufactured with technology, positioning itself as the great Spanish reference worldwide.

In 2020, TecAIRE has 300 coffee, cocoa and cereal projects in 30 countries around the world. These projects range from individual industrial equipment such as roasters for natural coffee, sugar coated coffee or cocoa; industrial coffee mills to complete plants and industrial plants for coffee, cocoa and spices.

TecAIRE more than just engineering since 1978

1978

TecAIRE group founded in Sabadell (Barcelona)

1983

International journey started in Argentina

1984

Activity extended to the cocoa industry

1985

TecAIRE experience used in roasting both cereals (such as sesame, chicory and tiger nuts) and alternative products (oak shavings, etc.)

2001

Breaks into African countries (Maghreb and sub-Saharan Africa)

2010

Introduction to Asian markets

2018

First industrial facilities in the Middle East

2020

TecAIRE is acquired by the European group Neocafé Engineering S.L.

TecAIRE is introduced in the development of projects of drying and grinding of spices (paprika, garlic, onion, etc...)

2022

400 projects in 30 countries worldwide

News TecAIRE

Company

News and novelties from TecAIRE

June 25, 2025

Coffee roasting: types, importance, temperatures and how they influence flavour

Discover the types of coffee roasts, their importance and how they influence the taste.

May 2, 2025

Specialty Coffee: what is it and how Barcelona is promoting a revolution in every cup?

What you need to know about Specialty Coffee and the importance of Barcelona in this…

April 22, 2025

TecAIRE coffee roasters: types and characteristics that make the difference

Discover the types of TecAIRE coffee roasters.

March 22, 2023

Trade fairs 2023

TecAIRE will attend a total of 5 international trade fairs of the food processing and…

December 21, 2022

TecAIRE adhered to the Positive Industry initiative promoted by AMEC

TecAIRE as a member of AMEC (Association of Internationalised Industrial Companies)…

November 25, 2022

TecAIRE becomes Genio Roasters global sales partner

TecAIRE and Genio Roasters sign a partnership agreement as commercial agents for Genio…

Contact

Company

What can we do for you?

Contact with Tecaire-Neocafé Engineering

TECAIRE is a Spanish company based in Terrassa (Barcelona).

Phone: +34 937 270 260

info@tecaire.com

Polígono Industrial 1 - Sector Can Petit. Carretera de Castellar, 520-522

Tell us about your project

Contact us to ask questions about our products or send us feedback or comments.