Drying Process

Drying and grinding processing

Archives Productos

Drying is a method of food preservation that consists of extracting water from food, which inhibits the proliferation of microorganisms and hinders putrefaction. Drying food by sun and wind to prevent spoilage has been practiced since ancient times. Water is usually removed by evaporation (air-drying, sun-drying, smoking or wind-drying).

Bacteria, yeasts and fungi need water in food to grow. Drying effectively prevents them from surviving in it.

Hundreds of millions of tons of wheat, corn, soybeans, rice and other grains such as sorghum, sunflower seed, rapeseed, barley, oats, etc. are dried in grain dehydrators.

That is why TecAIRE – Neocafé Engineering offers industrial dryer technology for the drying of fruits, vegetables and cereals.

Technical Characteristics

- Capacity of 60–120 kg coffee per cycle. Roasting drum

- Furnace with electronic progressive gas or diesel burner; low emissions

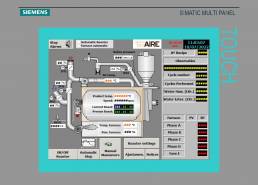

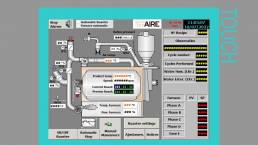

- PLC control panel and SIEMENS/AB colour touch screen

- Temperature and air pressure sensors installed in roaster heat sources and air ducts, to control roaster heat balance and prevent overheating and heat venting.

- Automated fire prevention systems, water injectors and burner operation monitoring.

Nothing found.

Processing Specialistfor premium Coffee and Cocoa

Grinding Process

Drying and Grinding Processing

Archives Productos

Drying is a method of preserving food by removing water from the food, which inhibits the growth of micro-organisms and makes putrefaction more difficult. Bacteria, yeasts and fungi need water in the food to grow. Drying effectively prevents them from surviving in it. The grinding methods are divided into two:

Types of milling

- Dry milling: This type of milling is carried out with totally dry materials or with very low humidity.

- Wet milling: The product to be milled may have moisture in it from the beginning or it may be moistened at some stage of the process.

Archives Productos

Dry milling

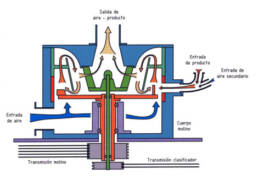

In order to increase the surface area of any solid, it is necessary to provide energy to the product by means of mechanical elements. To tackle both abnormal phenomena produced in any type of grinding (temperature and particle control), TecAIRE – NEOCAFÉ ENGINEERING presents the MS separator mill with which it is possible to grind at low temperature and control the particle size before it is extracted from the grinding chamber.

Mill MS-400

Separating mill to process particles up to 10MY

It has an independently driven grinding disc and separator, thus, by choosing the appropriate parameters and grinding elements, it can be used for all types of products by changing the internal elements of the classifier or mill.

The grinding disc can be equipped with different elements obtaining an impact, cutting or friction effect. The output size regulation is achieved by adjusting the speed and the air flow rate processed by the mill.

The grinding plant consists of a feeding system, a mill, a filter collector and a fan for cooling and conveying the product from the grinding chamber to the filter. Depending on the nature of the product and the final size required, it is possible to use a cyclone between the mill and the filter. The MS mill manages to minimise the temperature rise to very low levels, thus allowing the processing of materials with relatively low softening or melting points, e.g. stearates, resins or pharmaceutical intermediates.

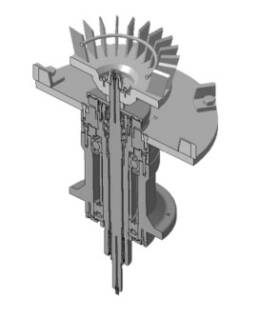

Hub MS-400

The heart of this separator mill is a combination of a grinding plate with pins or hammers and a classifying wheel (separator) driven by separate mechanical units controlled by frequency converters.

Mill MS-1500

The MS1500 and M2000 milling units are specially manufactured to process products where the need for production and fineness are very high, these processing units work at production rates of 10-20 Tn/hr and finenesses between 10 and 100 My. The power of the main motors ranges from 150 to 220 C.V. and their air flow rate from 14 to 20.000 m3/hr.

Grinding with continuous mechanical mills allows grinding of products with a hardness of up to 4 Mohs scale.

Technical Characteristics

| Modelo | Medida | MS-20 | MS-100 | MS-150 | MS-300 | MS-400 | MS-600 | MS-750 | MS-1000 | MS-1500 | MS-2000 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Diámetro molino | mm. | 185 | 325 | 325 | 494 | 494 | 774 | 774 | 970 | 970 | 1168 |

| Diámetro clasificador | mm. | 112 | 195 | 195 | 296 | 296 | 470 | 470 | 580 | 580 | 684 |

| Potencia molino | Kw. | 3 | 7,5 | 11 | 22 | 30 | 45 | 55 | 110 | 160 | 160 |

| Potencia clasificador | Kw. | 0,37 | 1,1 | 1,1 | 4 | 4 | 7,5 | 11 | 15 | 18,5 | 37 |

| Velocidad molino | r.p.m. min. | 6000 | 3000 | 3000 | 1500 | 1500 | 1000 | 1000 | 800 | 800 | 800 |

| r.p.m. max. | 10800 | 7200 | 7200 | 4700 | 4700 | 2900 | 2900 | 2600 | 2600 | 2200 | |

| Caudal aire | m3/h min. | 200 | 600 | 900 | 1500 | 2500 | 3000 | 4000 | 6500 | 8000 | 12000 |

| m3/h max. | 325 | 900 | 1350 | 3240 | 4200 | 6300 | 7200 | 9600 | 14400 | 19000 | |

| Factor de producción | 0,2 | 1 | 1,35 | 2,7 | 3,6 | 5,4 | 6,75 | 9 | 13,5 | 18 |

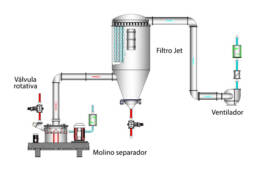

Diagram of grinding and solids separation line

The process diagram shows a pneumatic suction conveying circuit where we incorporate a rotary valve for product feeding, an MS separator mill where the particle reduction effect and particle size selection is carried out, a jet filter that separates the solids from the conveying air and a centrifugal fan that we use to classify the product and transport it to the filter.

This type of process units are used for the grinding and classification of products used in sectors such as food, minerals, phytosanitary products, paints and pigments, chemicals, etc.

Diagram of grinding and solids separation line

| PRODUCTO | FINURA | PRODUCCIÓN | MOLINO |

|---|---|---|---|

| Ácido Tartárico | 100% < 60 My | 400 Kg/hr | MS - 100 |

| Algarroba tostada | 100% < 74 My | 2000 Kg/hr | MS - 1500 |

| Azucar | 100% < 60 My | 3000 Kg/hr | MS - 400 |

| Baquelita | 99% < 2000 My | 450 Kg/hr | MS - 300 |

| Cacao 10/11% | 99% < 74 My | 4000 Kg/hr | MS - 1500 |

| Carbón | 100% < 40 My | 150 Kg/hr | MS - 150 |

| Carbonato cálcico | 99% < 100 My | 5000 Kg/hr | MS - 1500 |

| Colorante cerámico | 99% < 40 My | 400 Kg/hr | MS - 300 |

| Dolomita | 99% < 1000 My | 6500 Kg/hr | MS - 1500 |

| Epoxy | 99,5% < 100 My | 700 Kg/hr | MS - 400 |

| Estearatos | 100% < 40 My | 1500 Kg/hr | MS - 1000 |

| Garrofín | 100% < 74 My | 150 Kg/hr | MS - 1000 |

| Harina | 100% < 250 My | 750 Kg/hr | MS - 600 |

| Harina pescado | 100% < 800 My | 7500 Kg/hr | MS - 1500 |

| Herbicidas | 100% < 40 My | 500 Kg/hr | MS - 400 |

| Hidróxido aluminio | 100% < 20 My | 450 Kg/hr | MS - 400 |

| Naranjita | 100% < 200 My | 250 Kg/hr | MS - 300 |

| Pigmentos | 100% < 10 My | 500 Kg/hr | MS - 200 |

| Pimentón | 100% < 600 My | 650 Kg/hr | MS - 1000 |

| Pimienta | 99% < 700 My | 600 Kg/hr | MS - 400 |

| Producto farmacéutico | 100% < 10 My | 30 Kg/hr | MS - 20 |

| PVC (emulsión) | 100% < 60 My | 800 Kg/hr | MS - 600 |

| Resina novolaca | 100% < 100 My | 2500 Kg/hr | MS - 750 |

| Resina urea | 99% < 40 My | 2000 Kg/hr | MS - 600 |

| Rojo carmín | 100% < 20 My | 125 Kg/hr | MS - 100 |

| Soja en grano | 99% < 125 My | 600 Kg/hr | MS - 600 |

| Talco | 99% < 10 My | 1500 Kg/hr | MS - 1500 |

| Yeso | 99% < 100 My | 6000 Kg/hr | MS - 2000 |

Nothing found.

Processing Specialistfor premium Coffee and Cocoa

ACCURA Range

Coffee roasters

"ACCURA" range: Industrial roasters for natural coffee

Classic technology, designed for traditional processes.

"ACCURA" Range: 210–420 kg coffee beans roasted per hour

Roasters for traditional green coffee beans of regular size, particularly suitable for single origins. Roasting by the natural method, with no additives. Production capacity of 210–420 kg coffee per hour, depending on roast parameters.

Technical Characteristics

- Capacity of 60–120 kg coffee per cycle. Roasting drum

- Drum roasting 210–420 kg coffee beans roasted per hour

- Furnace with electronic progressive gas or diesel burner; low emissions

- Covered or open circular cooler with dual aspiration system

- Chaff collector

- PLC control panel and SIEMENS/AB colour touch screen

- Optional green coffee preheating system

- Optional smoke afterburner with or without catalyst

| Capacidad por tostado | Tiempo por ciclo | |

|---|---|---|

| TNA-60 / ACCURA | 30-60 Kg por ciclo | 12- 20 minutos |

| TNA-120 / ACCURA | 60-120 Kg por ciclo | 12- 20 minutos |

WHAT ARE THE MAIN FEATURES OF THE ‘ACCURA’ RANGE?

El tiempo de tostado de los tostadores gama ACCURA es de entre 12 a 20 minutos. Los tuestes cortos potencian la acidez del grano de café, mientras que los tiempos largos de tueste potencian el cuerpo del grano de café. Todos los tostadores admiten media carga o carga completa nominal, y el PLC corrige los tiempos y temperaturas de modo a homogeneizar los resultados de los perfiles de tueste.

- Homogeneous colour thanks to the method of heating the coffee bean using conduction (heat transfer from the roasting drum) and convection (heat transfer from hot air)

- Carbon steel or food grade stainless steel roasting drum with a variety of mixing paddles available in customised materials. Coffee moved evenly and carefully in the roasting drum to prevent damage to the bean.

- Degrees of roast, from light to dark, with the same capacity per cycle.

- Short and long roast times, with the same capacity per cycle.

- Weight loss depends on the moisture level in the green coffee bean, and can be compensated by the quenching system at the end of the roasting process.

- Rapid and careful cooling to prevent damage to the coffee bean

- Roasting and cooling cycles are synchronised and occur simultaneously

- Roasters equipped with evacuation cyclones for the chaff, which can be collected or burnt

WHAT IS ENVIRONMENTAL CARE?

Ahorro energético y respeto medioambiental en las emisiones atmosféricas, y desechos sólidos y líquidos.

- Potential to add a smoke afterburner with catalyst to both the roaster and cooler exhausts

- Installation of dust and solid particle filters to prevent emission to the exterior.

- Reducing emissions and complying with local, regional and national limits.

- Insulating heat sources in the roaster, smoke afterburner and exhausts.

WHAT SPECIFIC FEATURES ARE INCLUDED?

Los equipos garantizan un alto grado de rendimiento y seguridad en su funcionamiento.

- Compliance with local safety regulations related to the machinery, products and staff operating the roaster

- Maintenance and repair protocol. Immediate availability of standard parts that affect machine safety; easy and economical maintenance.

- Quick and easy access to clean the roaster and replace worn parts.

- Temperature and air pressure sensors installed in roaster heat sources and air ducts, to control roaster heat balance and prevent overheating and heat venting.

- Automated fire prevention systems, water injectors and burner operation monitoring.

Nothing found.

Processing Specialistfor premium Coffee and Cocoa

QC Series

Tostadoras para café i proceso de cacao

Archives Productos

Technical Characteristics

- Testing equipment: monitoring moisture, density, particle size, screening, acidity and colour.

- Centralised booths to warn, evaluate and correct operational parameters at each stage of the process.

- Software and assistance for compliance with standards – ISO, IFS.

- SIEMENS / AB programming

- Safety monitoring for operating systems

- Software to manage product traceability.

Nothing found.

Processing Specialistfor premium Coffee and Cocoa

QH Series

Tostadoras para café i proceso de cacao

Archives Productos

Technical Characteristics

- Afterburn system for roasting air

- Catalysts to treat heat sources

- Energy recycling by recirculation – energy saving

- Water recycling using carbon systems

- Chaff compaction into pellets

- Solid particle extraction from the roasting and cooling system

- Online analysis of particle emissions

- Energy-efficient electrical equipment

- Energy-efficient burners

- Green coffee preheating

Nothing found.