Drying and Grinding Processing

Grinding Process

Drying is a method of preserving food by removing water from the food, which inhibits the growth of micro-organisms and makes putrefaction more difficult. Bacteria, yeasts and fungi need water in the food to grow. Drying effectively prevents them from surviving in it. The grinding methods are divided into two:

Types of milling

- Dry milling: This type of milling is carried out with totally dry materials or with very low humidity.

- Wet milling: The product to be milled may have moisture in it from the beginning or it may be moistened at some stage of the process.

Grinding Process

Dry milling

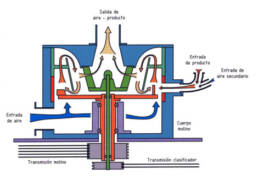

In order to increase the surface area of any solid, it is necessary to provide energy to the product by means of mechanical elements. To tackle both abnormal phenomena produced in any type of grinding (temperature and particle control), TecAIRE – NEOCAFÉ ENGINEERING presents the MS separator mill with which it is possible to grind at low temperature and control the particle size before it is extracted from the grinding chamber.

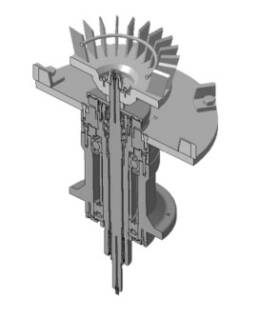

Mill MS-400

Separating mill to process particles up to 10MY

It has an independently driven grinding disc and separator, thus, by choosing the appropriate parameters and grinding elements, it can be used for all types of products by changing the internal elements of the classifier or mill.

The grinding disc can be equipped with different elements obtaining an impact, cutting or friction effect. The output size regulation is achieved by adjusting the speed and the air flow rate processed by the mill.

The grinding plant consists of a feeding system, a mill, a filter collector and a fan for cooling and conveying the product from the grinding chamber to the filter. Depending on the nature of the product and the final size required, it is possible to use a cyclone between the mill and the filter. The MS mill manages to minimise the temperature rise to very low levels, thus allowing the processing of materials with relatively low softening or melting points, e.g. stearates, resins or pharmaceutical intermediates.

Hub MS-400

The heart of this separator mill is a combination of a grinding plate with pins or hammers and a classifying wheel (separator) driven by separate mechanical units controlled by frequency converters.

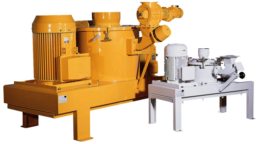

Mill MS-1500

The MS1500 and M2000 milling units are specially manufactured to process products where the need for production and fineness are very high, these processing units work at production rates of 10-20 Tn/hr and finenesses between 10 and 100 My. The power of the main motors ranges from 150 to 220 C.V. and their air flow rate from 14 to 20.000 m3/hr.

Grinding with continuous mechanical mills allows grinding of products with a hardness of up to 4 Mohs scale.

Technical Characteristics

| Modelo | Medida | MS-20 | MS-100 | MS-150 | MS-300 | MS-400 | MS-600 | MS-750 | MS-1000 | MS-1500 | MS-2000 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Diámetro molino | mm. | 185 | 325 | 325 | 494 | 494 | 774 | 774 | 970 | 970 | 1168 |

| Diámetro clasificador | mm. | 112 | 195 | 195 | 296 | 296 | 470 | 470 | 580 | 580 | 684 |

| Potencia molino | Kw. | 3 | 7,5 | 11 | 22 | 30 | 45 | 55 | 110 | 160 | 160 |

| Potencia clasificador | Kw. | 0,37 | 1,1 | 1,1 | 4 | 4 | 7,5 | 11 | 15 | 18,5 | 37 |

| Velocidad molino | r.p.m. min. | 6000 | 3000 | 3000 | 1500 | 1500 | 1000 | 1000 | 800 | 800 | 800 |

| r.p.m. max. | 10800 | 7200 | 7200 | 4700 | 4700 | 2900 | 2900 | 2600 | 2600 | 2200 | |

| Caudal aire | m3/h min. | 200 | 600 | 900 | 1500 | 2500 | 3000 | 4000 | 6500 | 8000 | 12000 |

| m3/h max. | 325 | 900 | 1350 | 3240 | 4200 | 6300 | 7200 | 9600 | 14400 | 19000 | |

| Factor de producción | 0,2 | 1 | 1,35 | 2,7 | 3,6 | 5,4 | 6,75 | 9 | 13,5 | 18 |

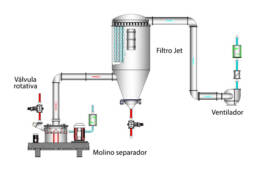

Diagram of grinding and solids separation line

The process diagram shows a pneumatic suction conveying circuit where we incorporate a rotary valve for product feeding, an MS separator mill where the particle reduction effect and particle size selection is carried out, a jet filter that separates the solids from the conveying air and a centrifugal fan that we use to classify the product and transport it to the filter.

This type of process units are used for the grinding and classification of products used in sectors such as food, minerals, phytosanitary products, paints and pigments, chemicals, etc.

Diagram of grinding and solids separation line

| PRODUCTO | FINURA | PRODUCCIÓN | MOLINO |

|---|---|---|---|

| Ácido Tartárico | 100% < 60 My | 400 Kg/hr | MS - 100 |

| Algarroba tostada | 100% < 74 My | 2000 Kg/hr | MS - 1500 |

| Azucar | 100% < 60 My | 3000 Kg/hr | MS - 400 |

| Baquelita | 99% < 2000 My | 450 Kg/hr | MS - 300 |

| Cacao 10/11% | 99% < 74 My | 4000 Kg/hr | MS - 1500 |

| Carbón | 100% < 40 My | 150 Kg/hr | MS - 150 |

| Carbonato cálcico | 99% < 100 My | 5000 Kg/hr | MS - 1500 |

| Colorante cerámico | 99% < 40 My | 400 Kg/hr | MS - 300 |

| Dolomita | 99% < 1000 My | 6500 Kg/hr | MS - 1500 |

| Epoxy | 99,5% < 100 My | 700 Kg/hr | MS - 400 |

| Estearatos | 100% < 40 My | 1500 Kg/hr | MS - 1000 |

| Garrofín | 100% < 74 My | 150 Kg/hr | MS - 1000 |

| Harina | 100% < 250 My | 750 Kg/hr | MS - 600 |

| Harina pescado | 100% < 800 My | 7500 Kg/hr | MS - 1500 |

| Herbicidas | 100% < 40 My | 500 Kg/hr | MS - 400 |

| Hidróxido aluminio | 100% < 20 My | 450 Kg/hr | MS - 400 |

| Naranjita | 100% < 200 My | 250 Kg/hr | MS - 300 |

| Pigmentos | 100% < 10 My | 500 Kg/hr | MS - 200 |

| Pimentón | 100% < 600 My | 650 Kg/hr | MS - 1000 |

| Pimienta | 99% < 700 My | 600 Kg/hr | MS - 400 |

| Producto farmacéutico | 100% < 10 My | 30 Kg/hr | MS - 20 |

| PVC (emulsión) | 100% < 60 My | 800 Kg/hr | MS - 600 |

| Resina novolaca | 100% < 100 My | 2500 Kg/hr | MS - 750 |

| Resina urea | 99% < 40 My | 2000 Kg/hr | MS - 600 |

| Rojo carmín | 100% < 20 My | 125 Kg/hr | MS - 100 |

| Soja en grano | 99% < 125 My | 600 Kg/hr | MS - 600 |

| Talco | 99% < 10 My | 1500 Kg/hr | MS - 1500 |

| Yeso | 99% < 100 My | 6000 Kg/hr | MS - 2000 |